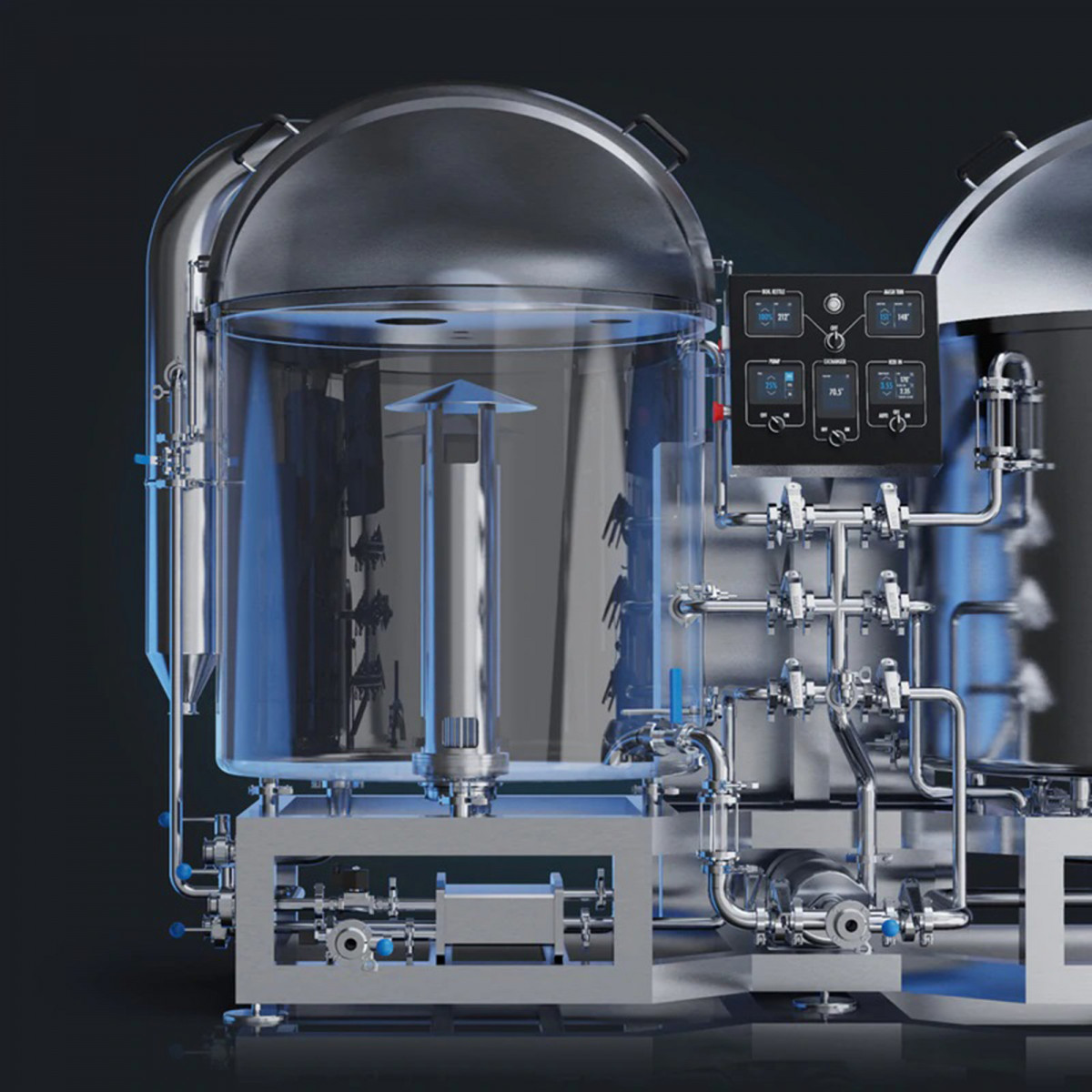

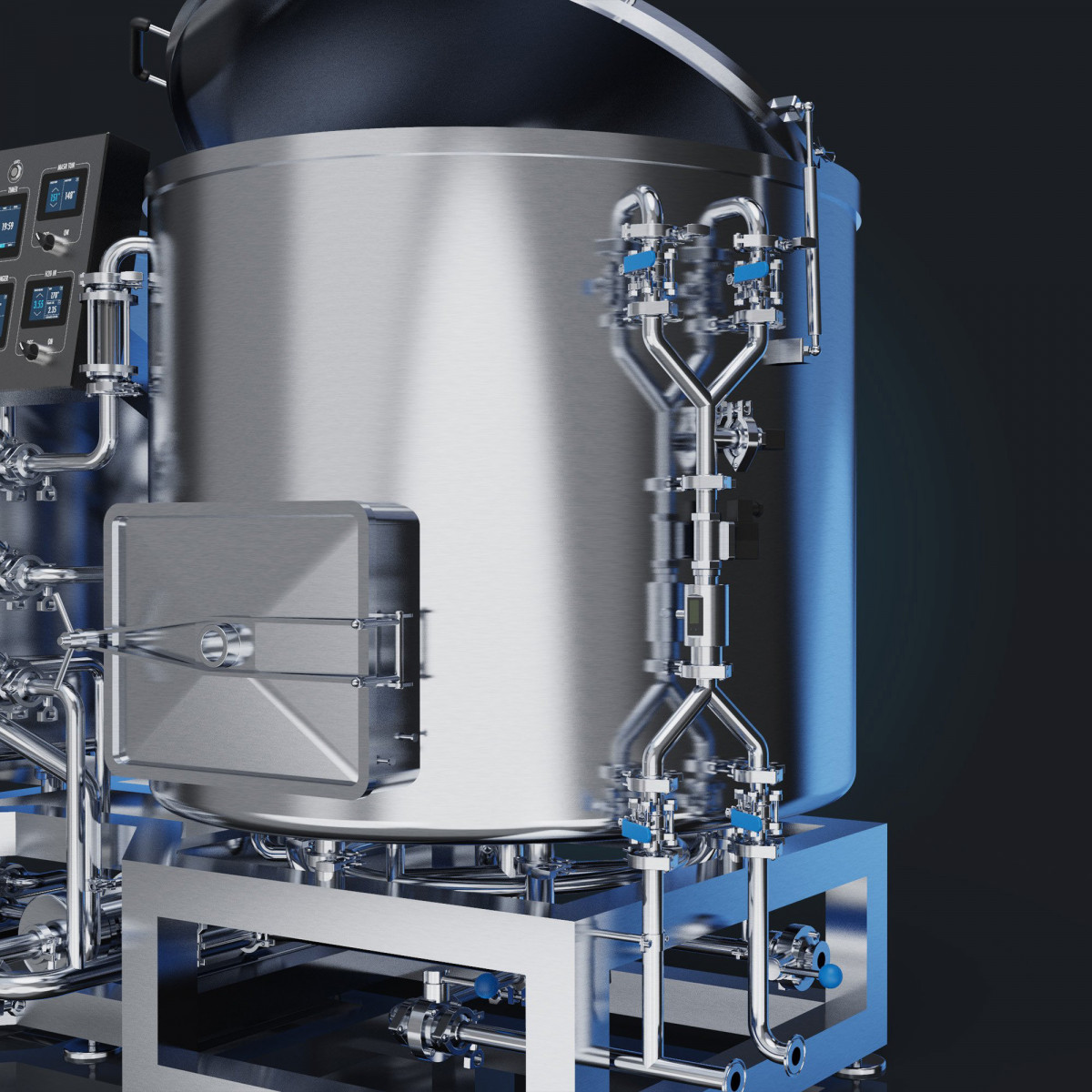

Designed and engineered alongside the expansive line of professional brewhouses, the 3.5 bbl Ss Brewhouse is the sweet spot for a start-up brewery, brewpub, or the perfect pilot system for a larger production brewery.

Designed and engineered alongside the expansive line of professional brewhouses, the 3.5 bbl Ss Brewhouse is the sweet spot for a start-up brewery, brewpub, or the perfect pilot system for a larger production brewery.

The 3.5 bbl Ss Brewhouse is the most advanced nano brewhouse on the market.

Professional Design

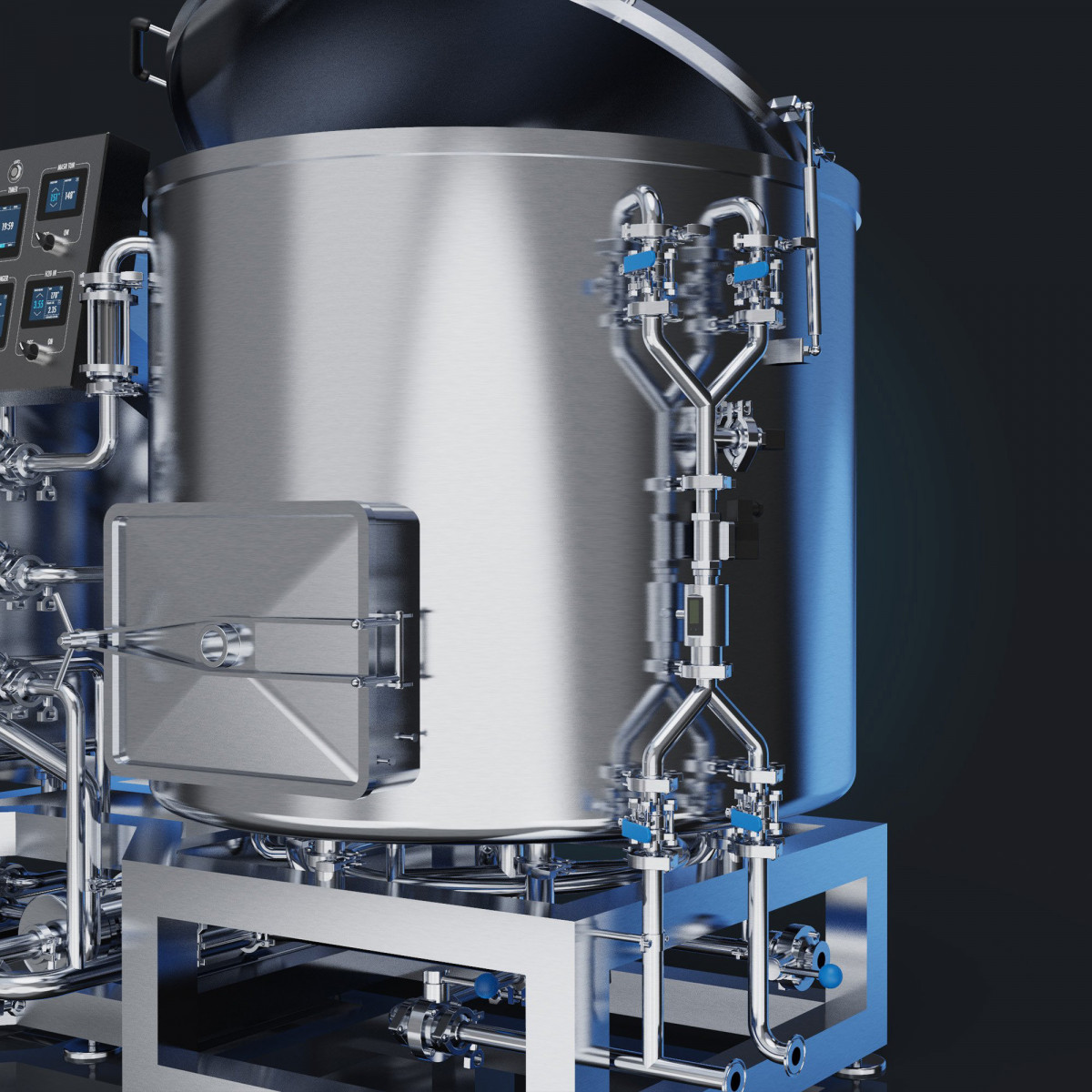

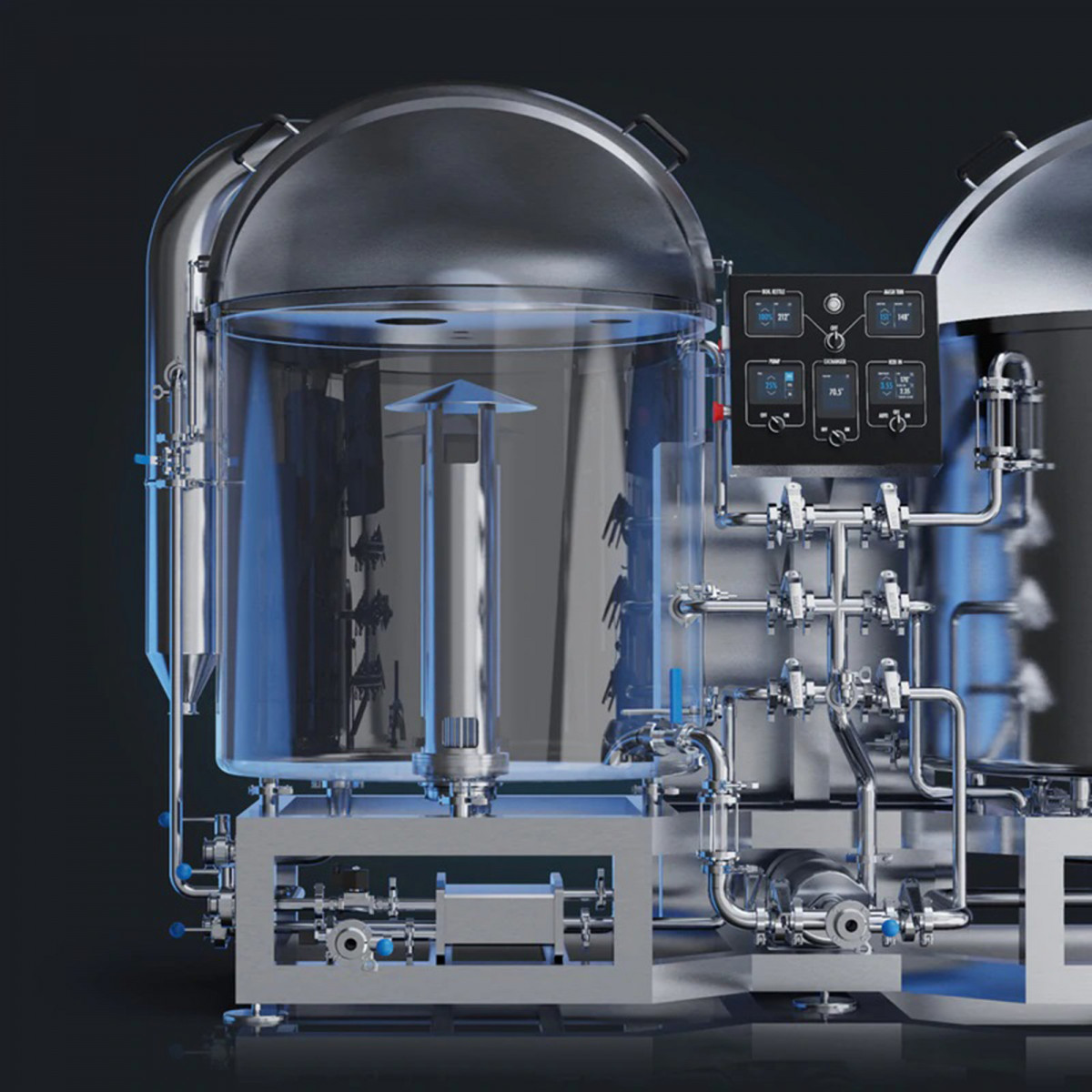

The 3.5 bbl Ss Brewhouse is designed to share many of the same features as their Pro brewhouses. The frame-mounted components, brewer-centric valve tree, grain-out door, milled false bottom, and the patent-pending internal calandria define this as a genuinely professional-grade brewhouse.

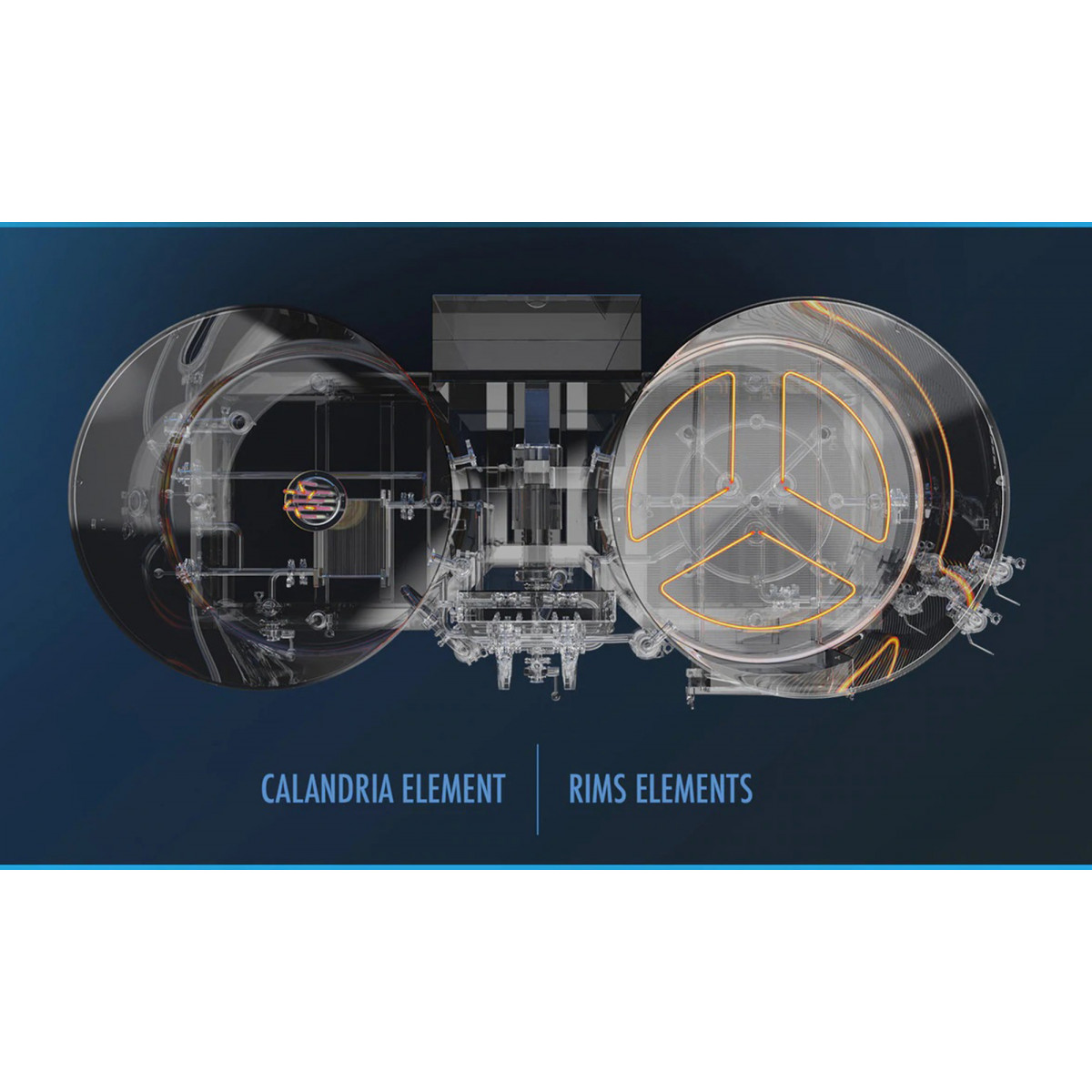

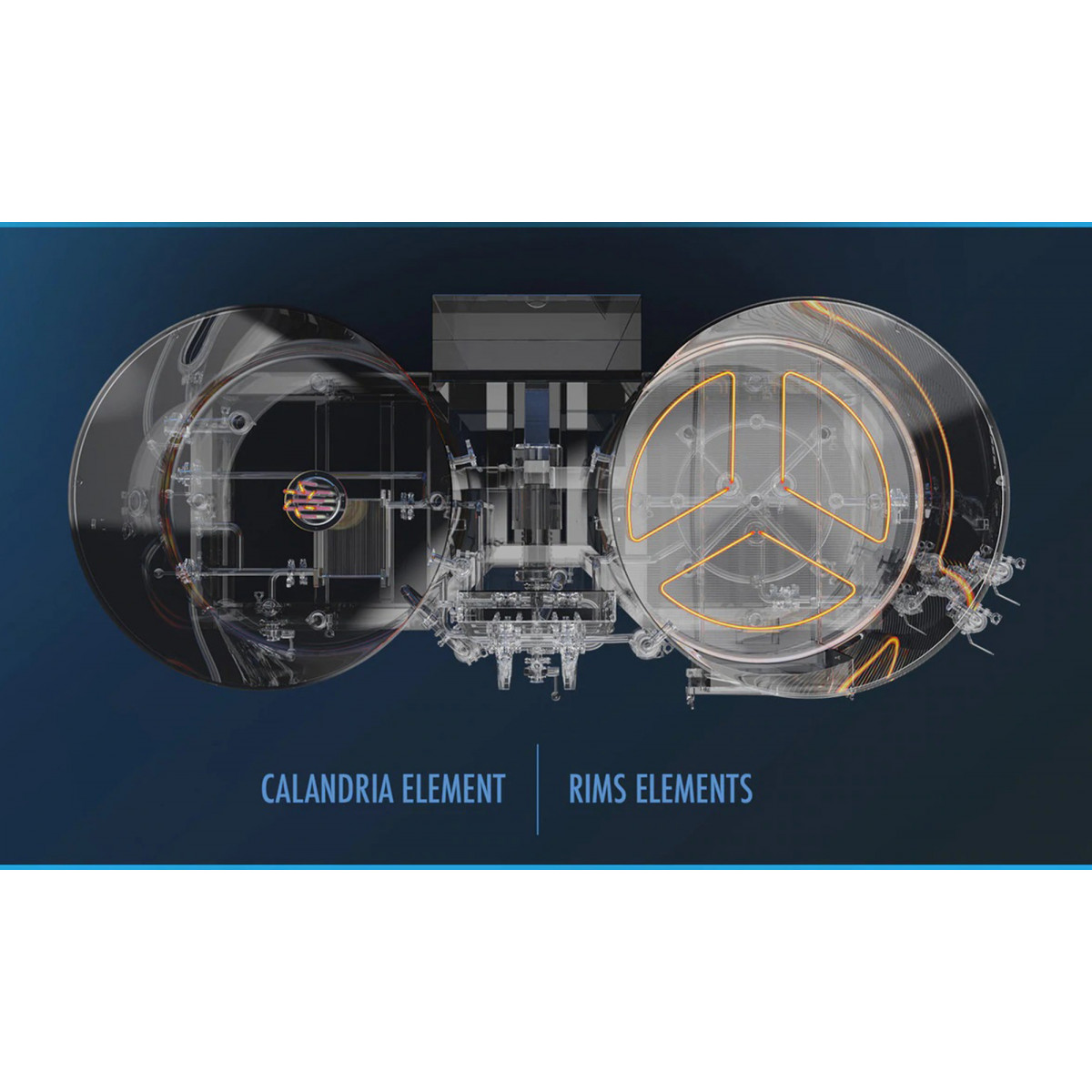

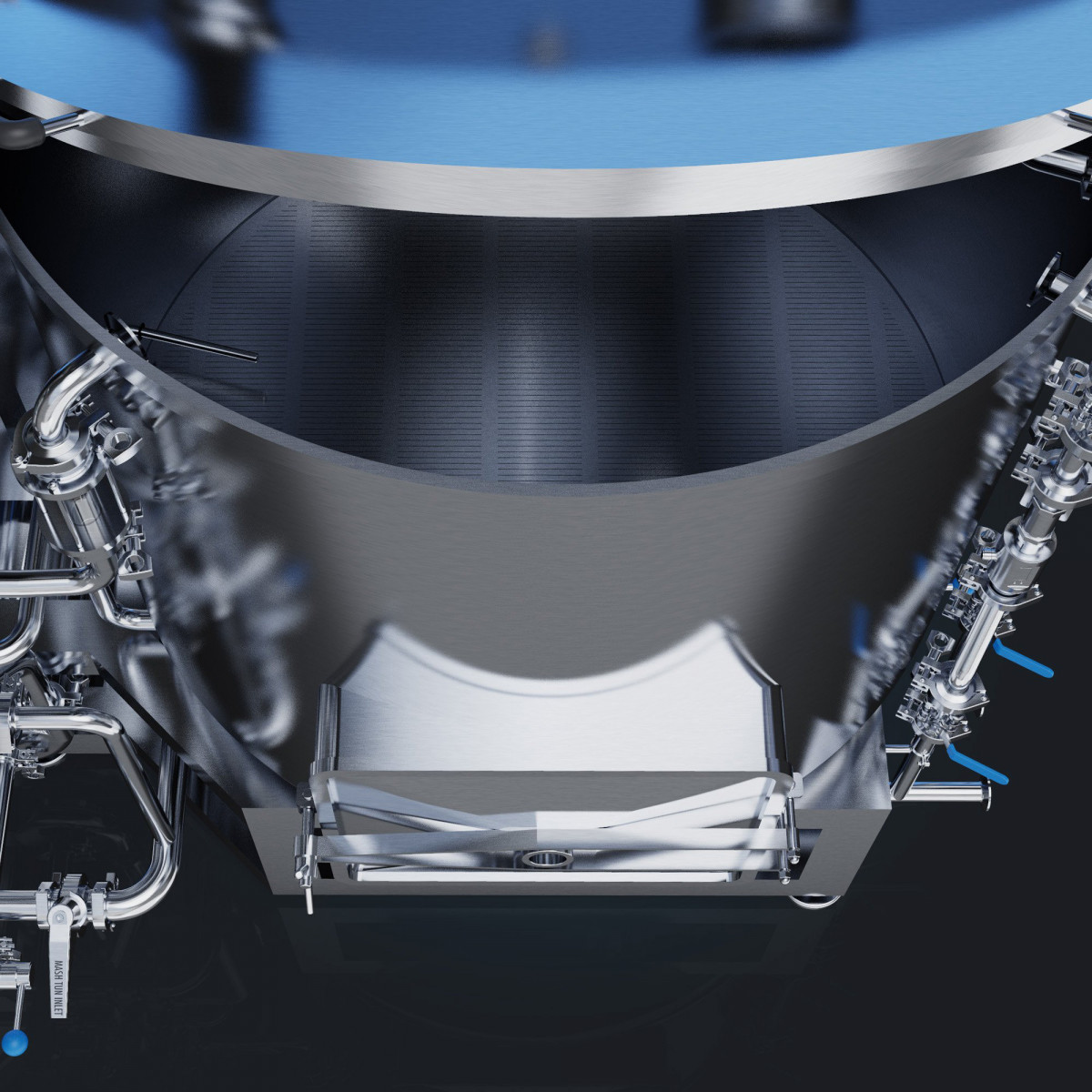

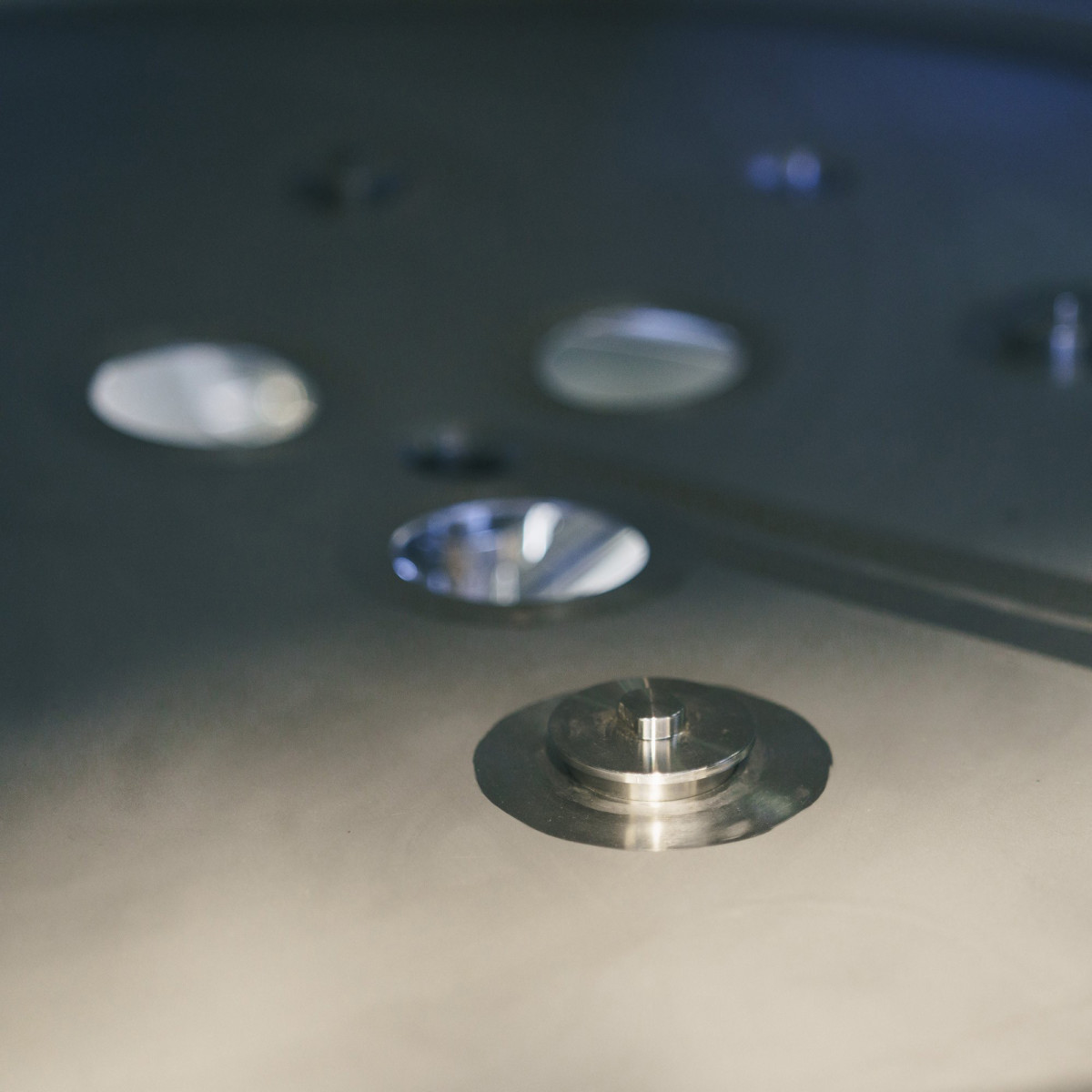

Patent Pending Internal Calandria 2.0

External calandrias are widely used in large scale (+50 bbl) professional brewhouses, and for good reason, a calandria vastly improves the efficiency of a brewhouse by requiring less energy to achieve an effective boil. The Ss Brewtech Patent Pending internal calandria takes the essential elements of an external calandria and places them directly in the kettle. The natural convection of the liquid removes the need for the additional complication of a calandria pump. Version 2.0 incorporates sealed magnets into the base of the shell to allow for easy removal and cleaning.

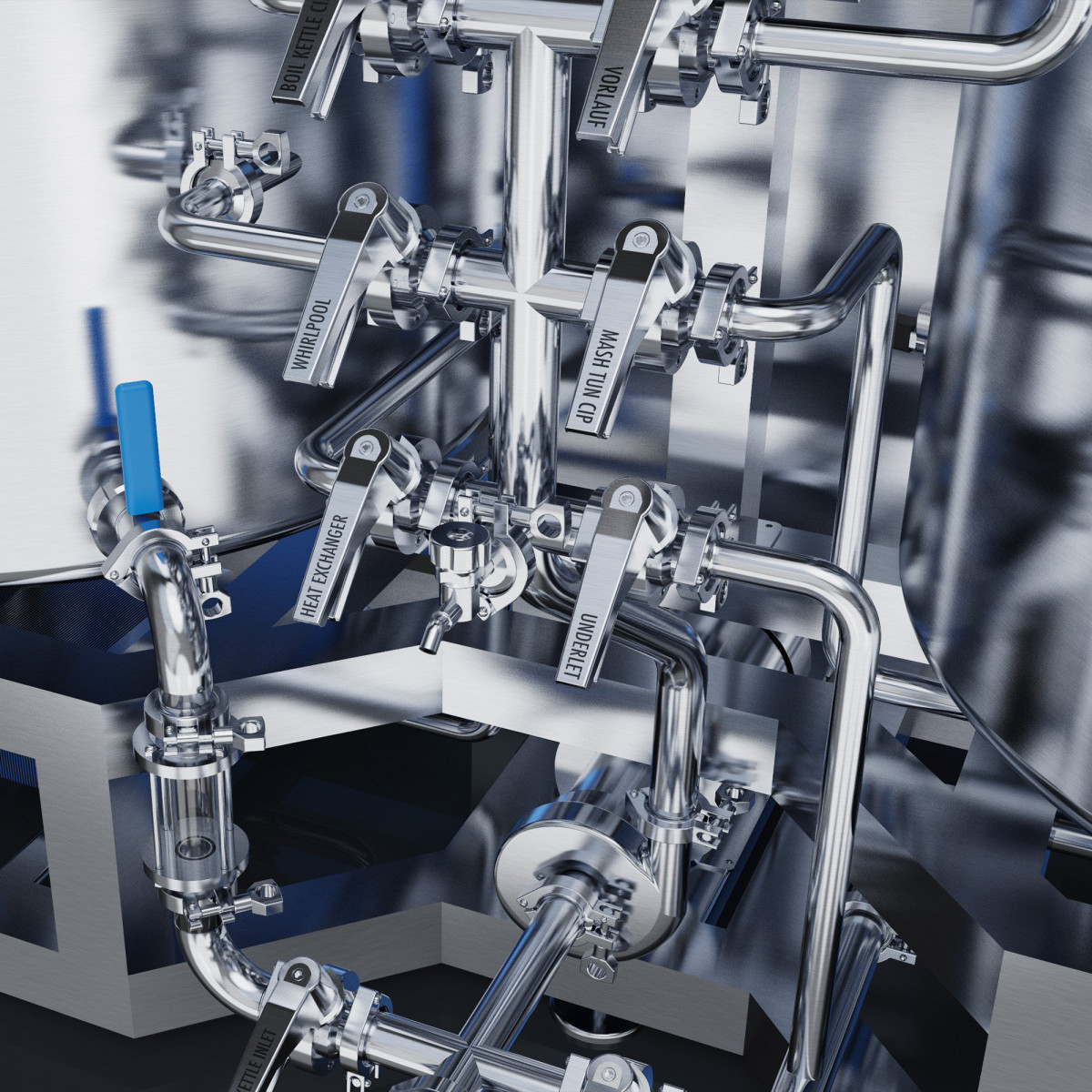

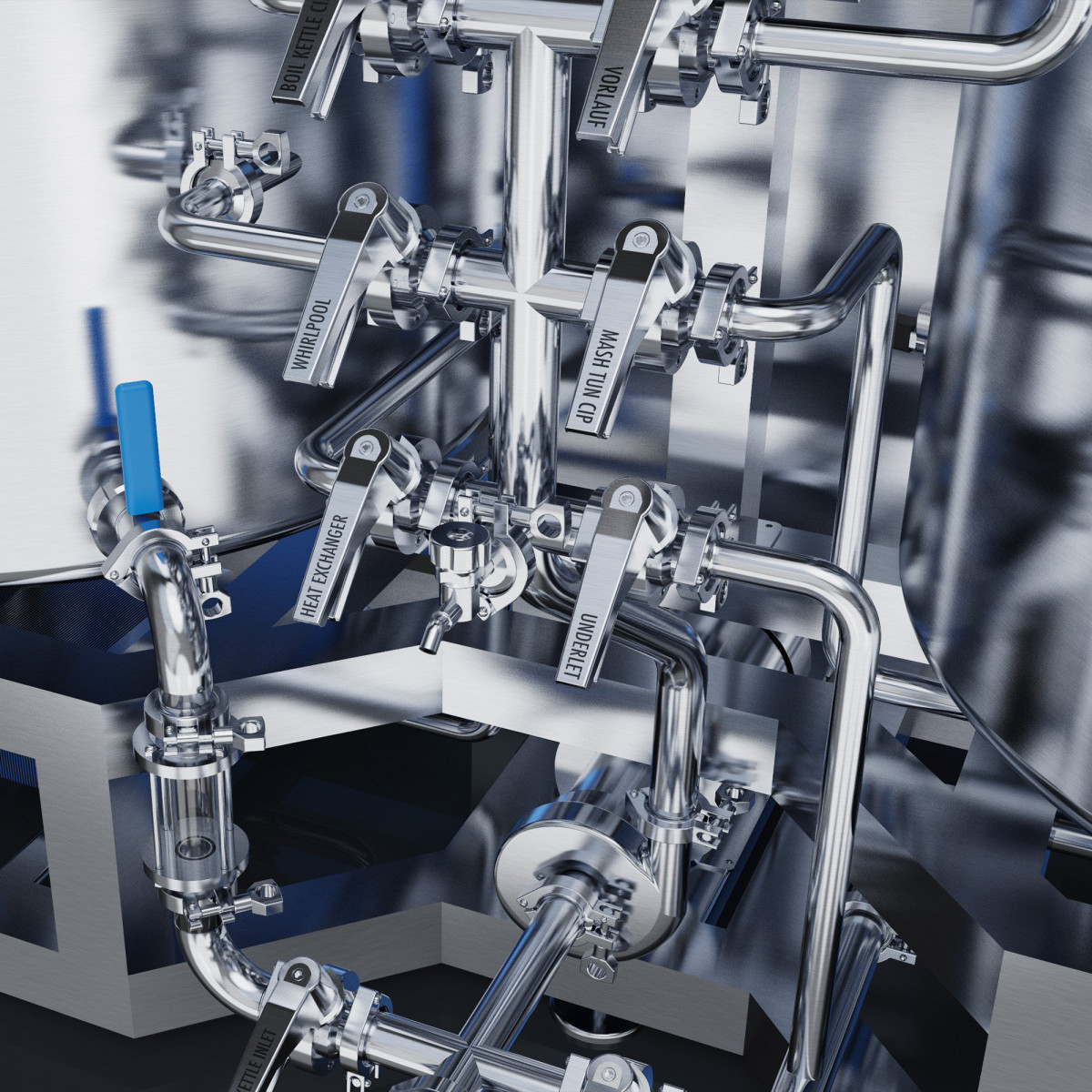

Touch Controls & Pro Valve Tree

A fundamental design element for Ss Brewtech Pro Brewhouses has always been brewer-centric control. Having all the process-significant valves on a centralised tree allows for quick and accurate adjustments during your brew day. The 3.5 bbl Brewhouse incorporates Ss Brewtech's reimagined user interface. The new control panel design incorporates touch controllers and the ability to automate some key functions. The result is a brewhouse with a much higher degree of precision than ever before.

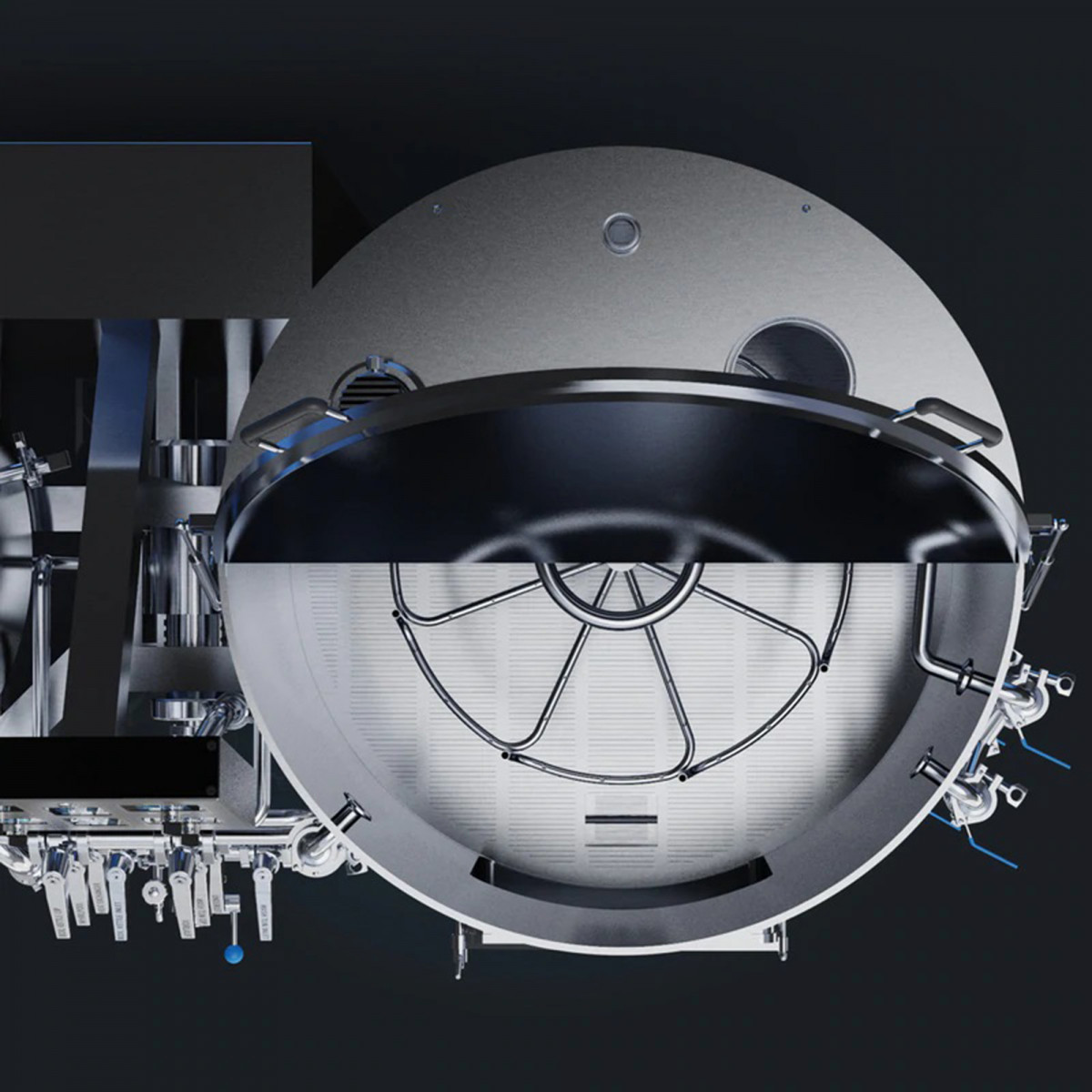

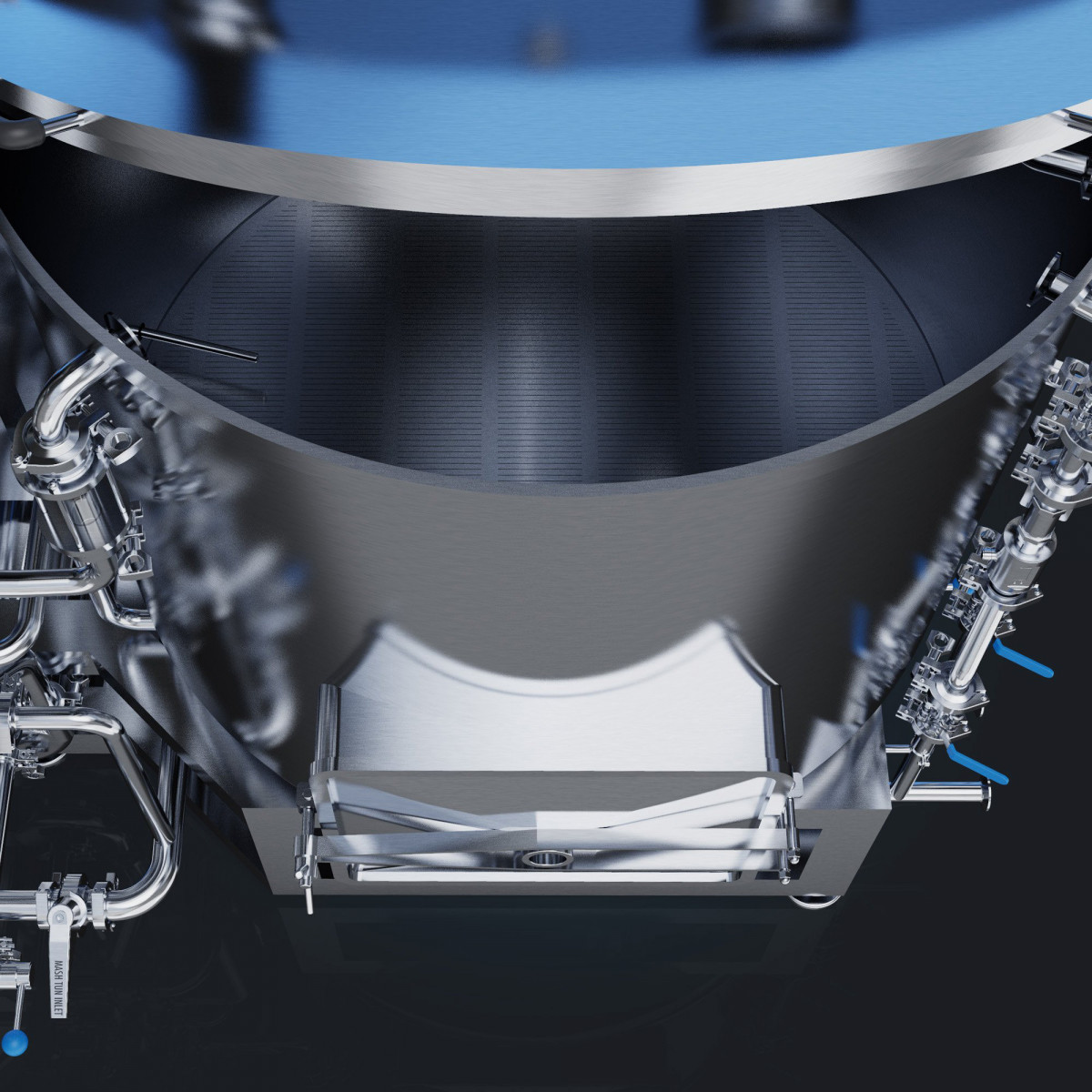

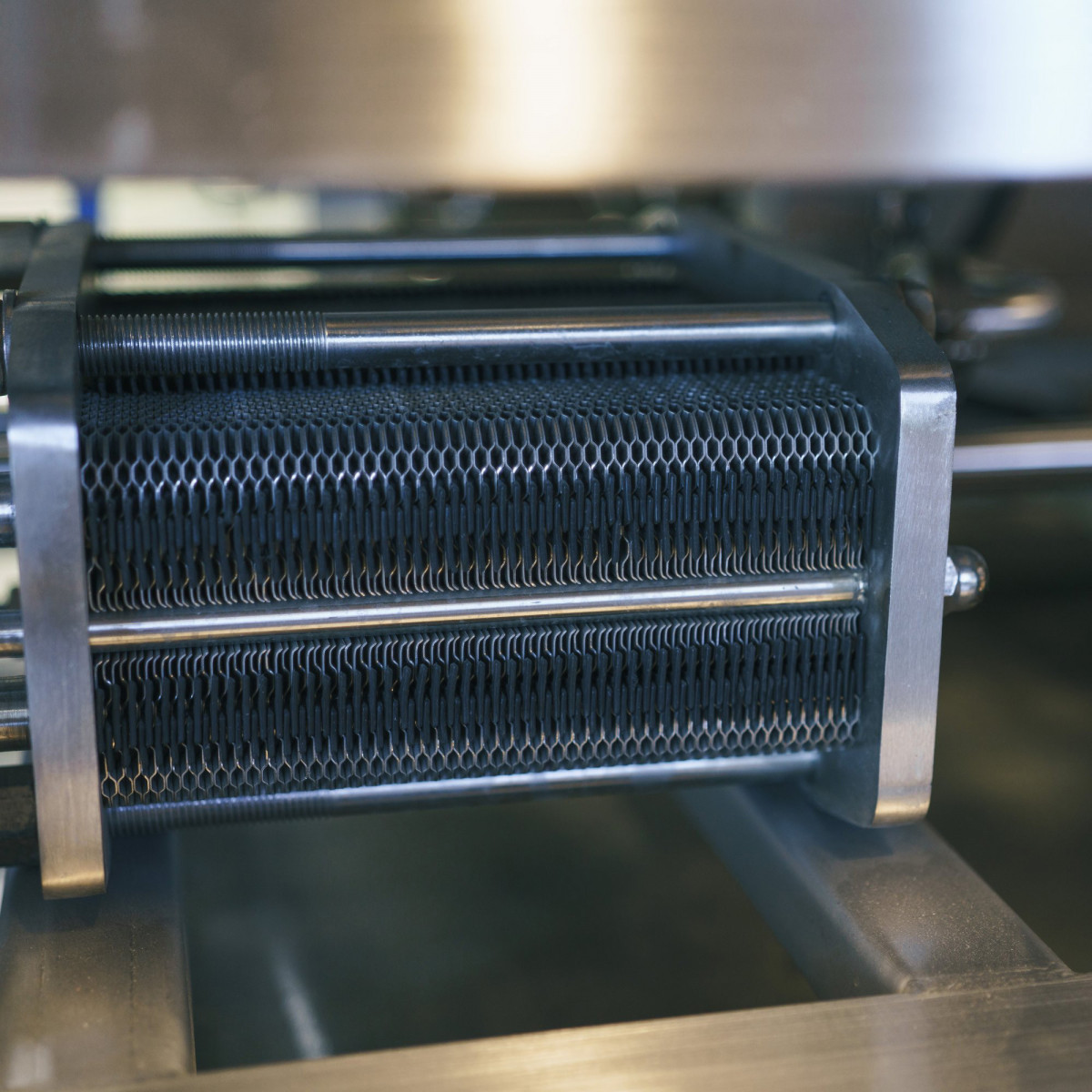

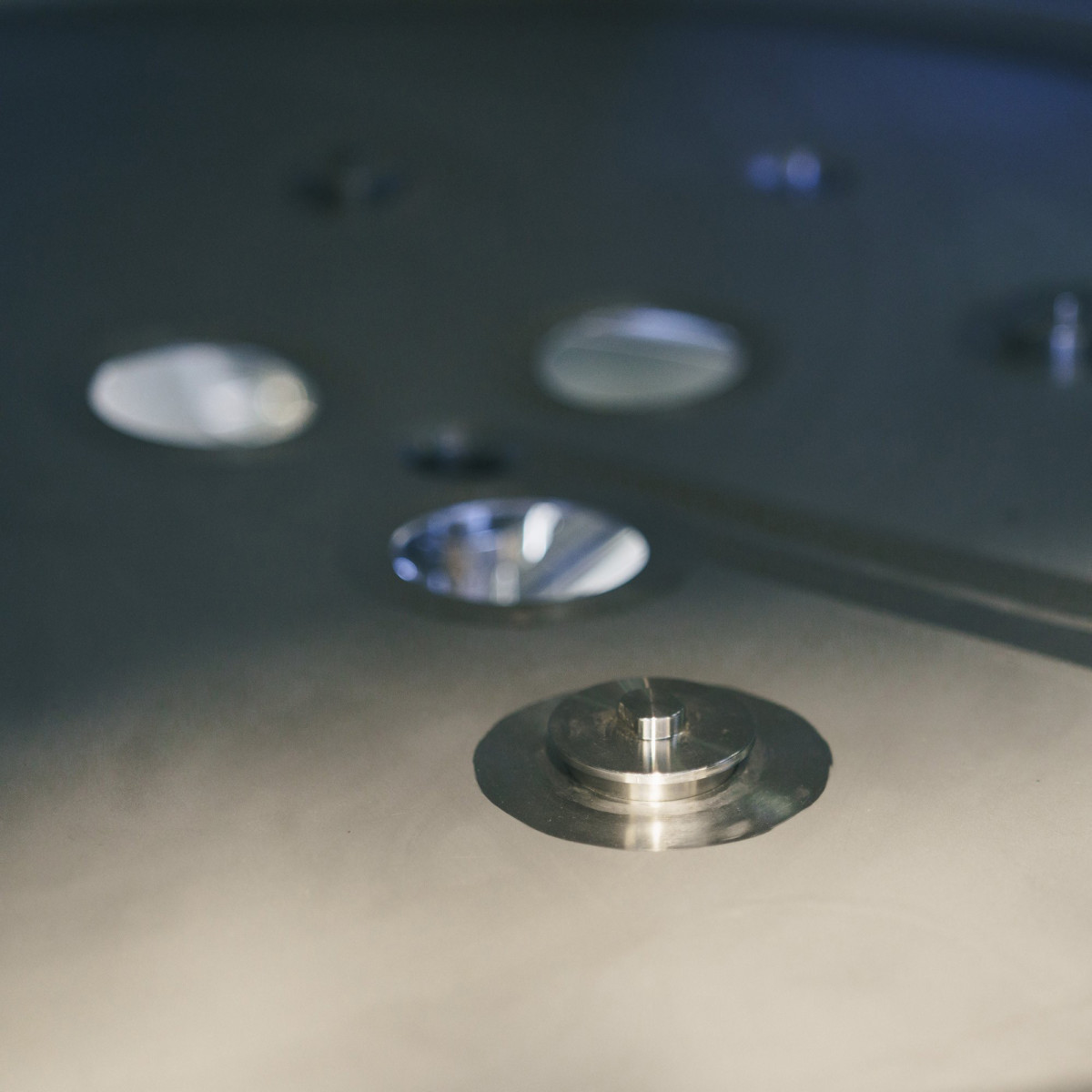

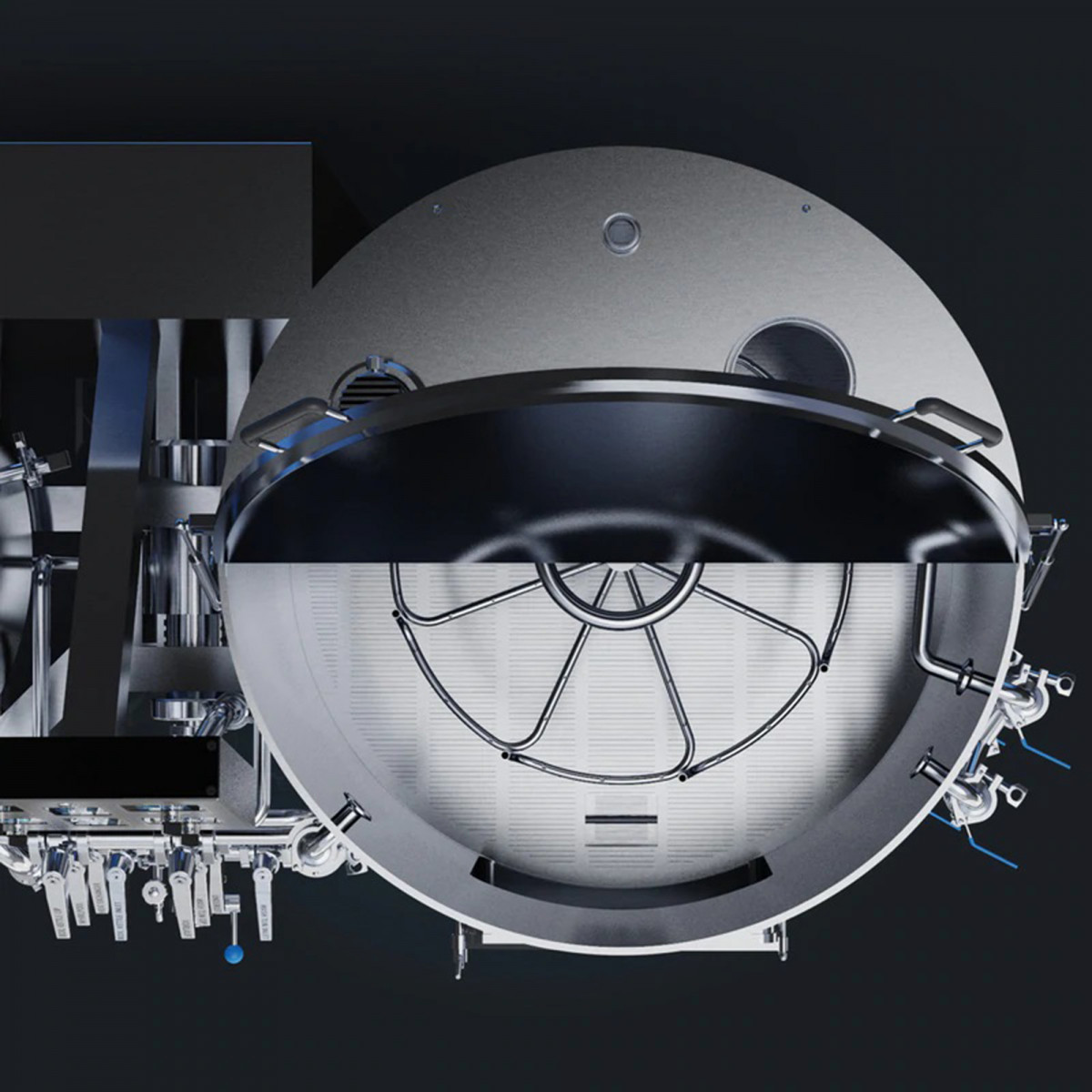

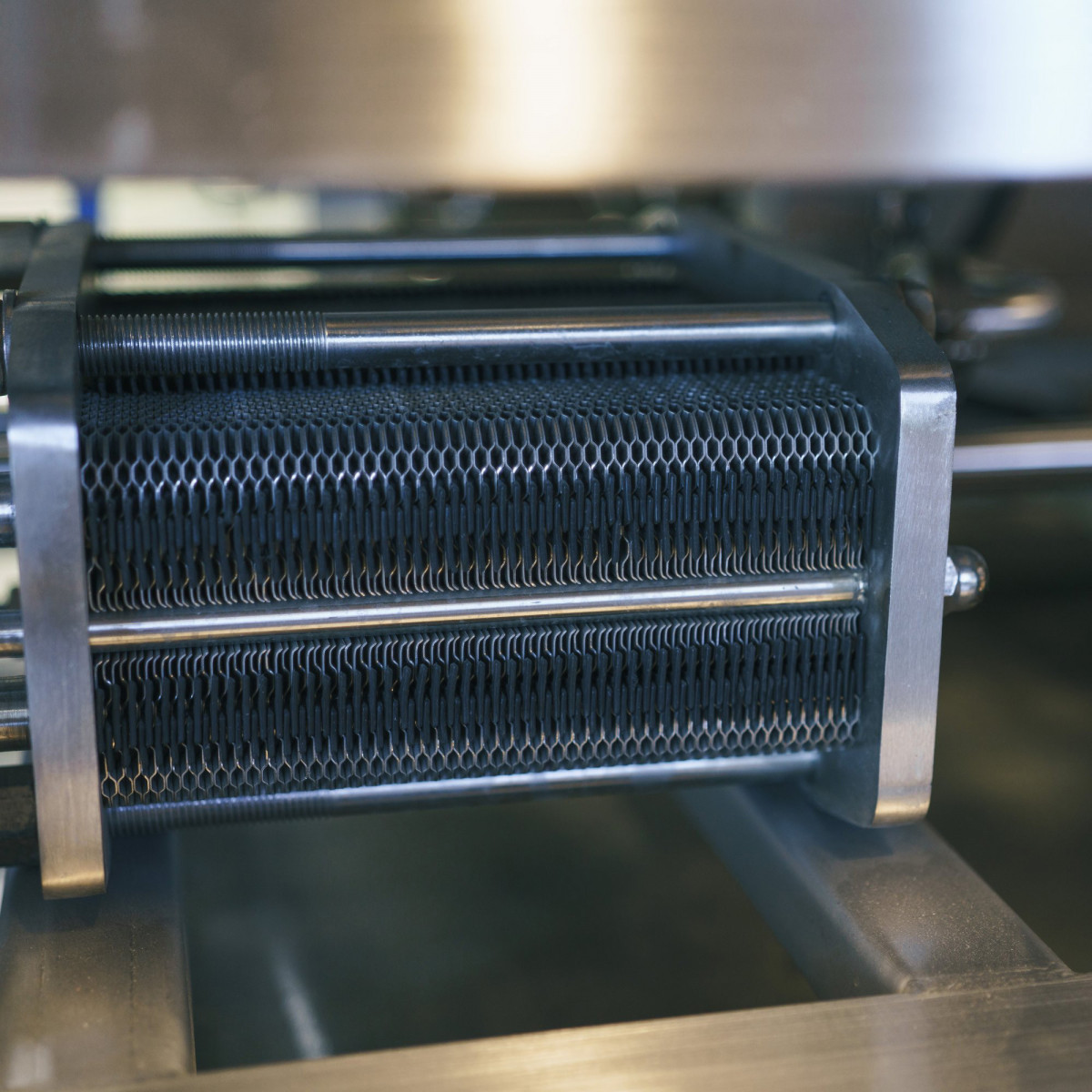

Milled False Bottom & Grain-Out Door

Milling slots into a solid plate of stainless steel is widely considered the most precise way to manufacture a false bottom. For the 3.5 bbl Brewhouse, we didn't just stop at a milled false bottom, we also added a professional flush-mount grain-out door for easy removal of spent grain. Nestled beneath the false bottom is an array of 5 wort outlet ports contributing to a balanced runoff, and 3 heating element pro version of a Recirculation Infusion Mash System (RIMS) for more exacting temperature control resulting in clearer wort and increased extraction.

NO2 Spring Assisted Lids & Accessories

The gas spring assisted lids make getting a paddle into the mash tun easy, while also maintaining the ability to close the lids for better thermal efficiency and storage. The back half of the lids incorporate lights and accessory ports for future upgrades.

Features:

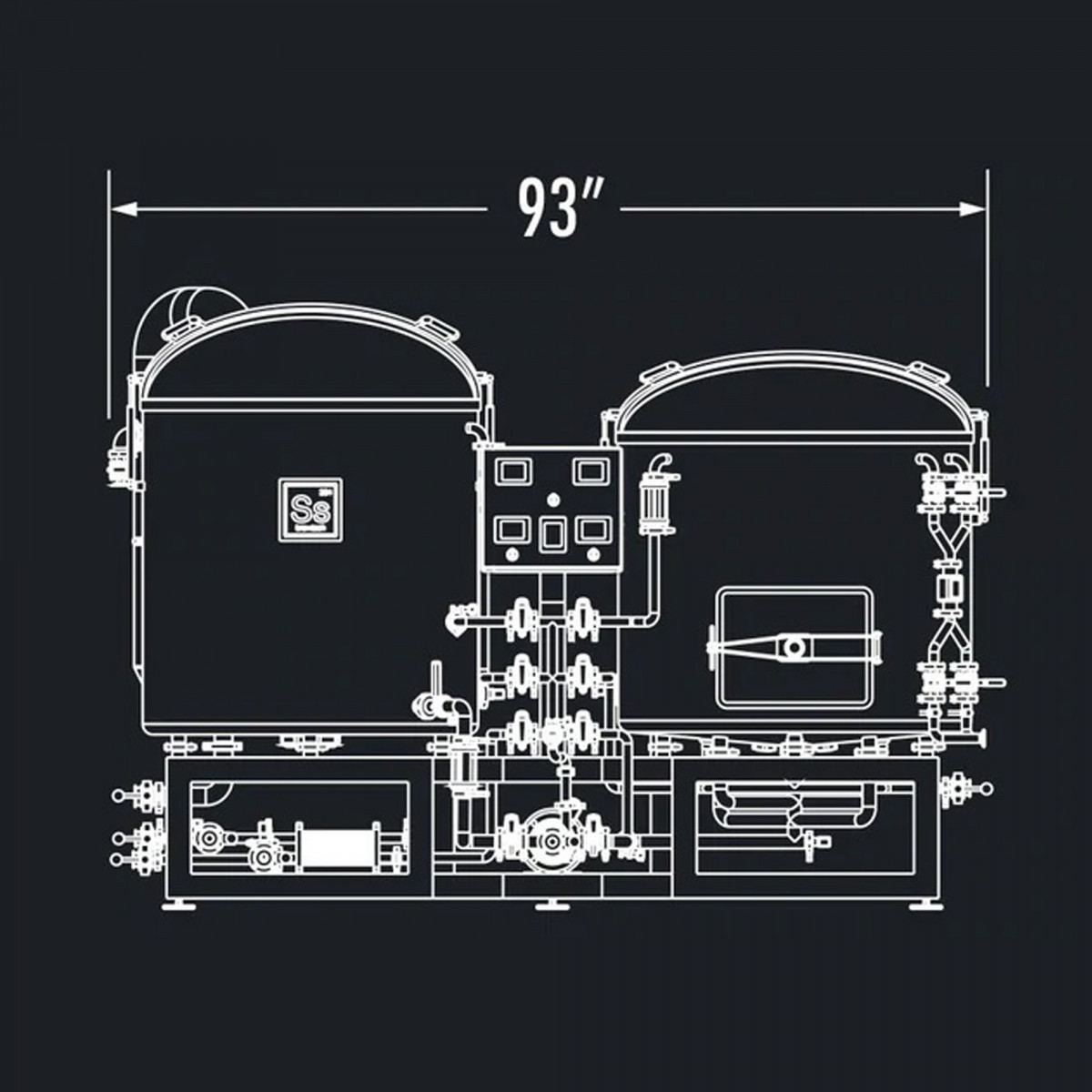

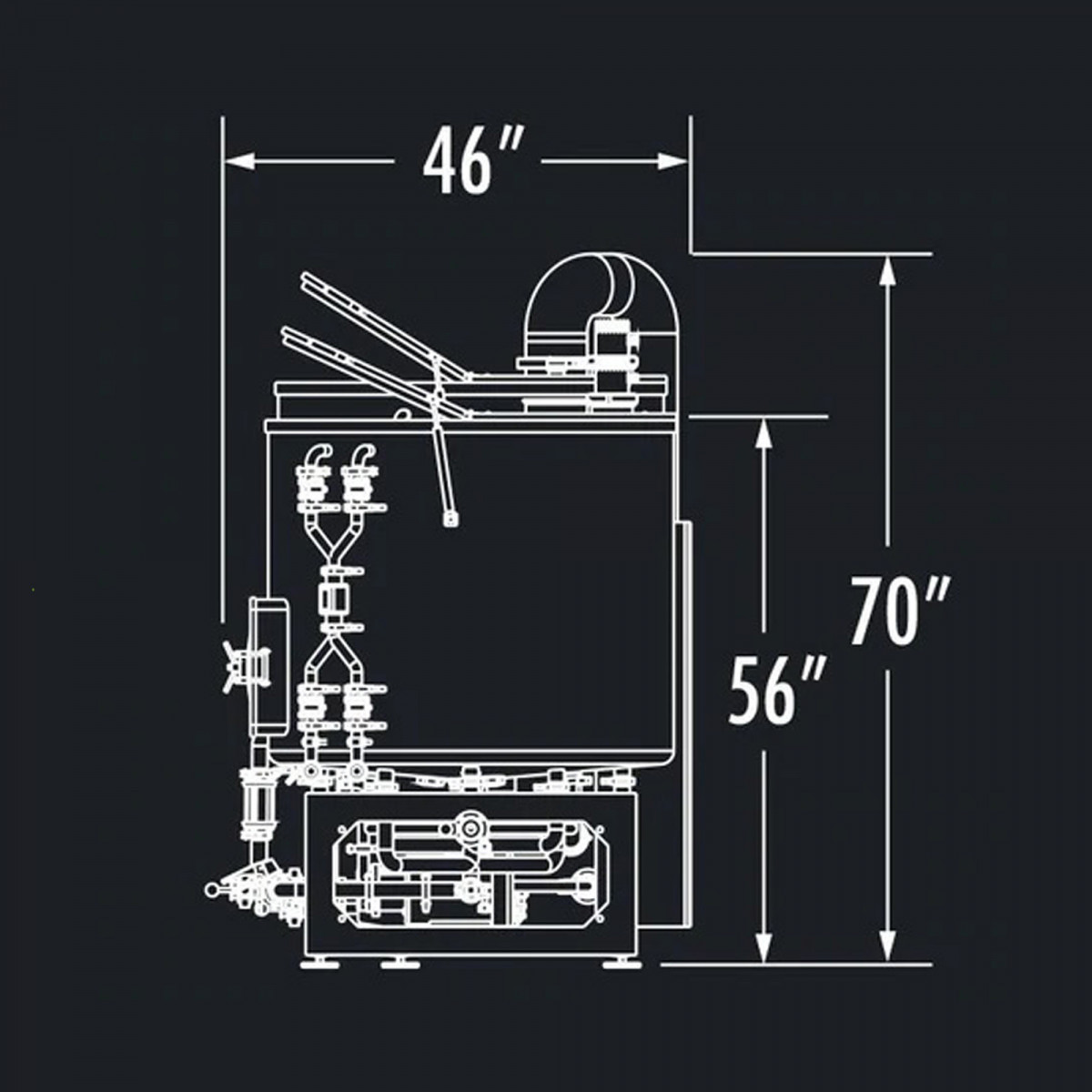

Specifications:

Data sheet

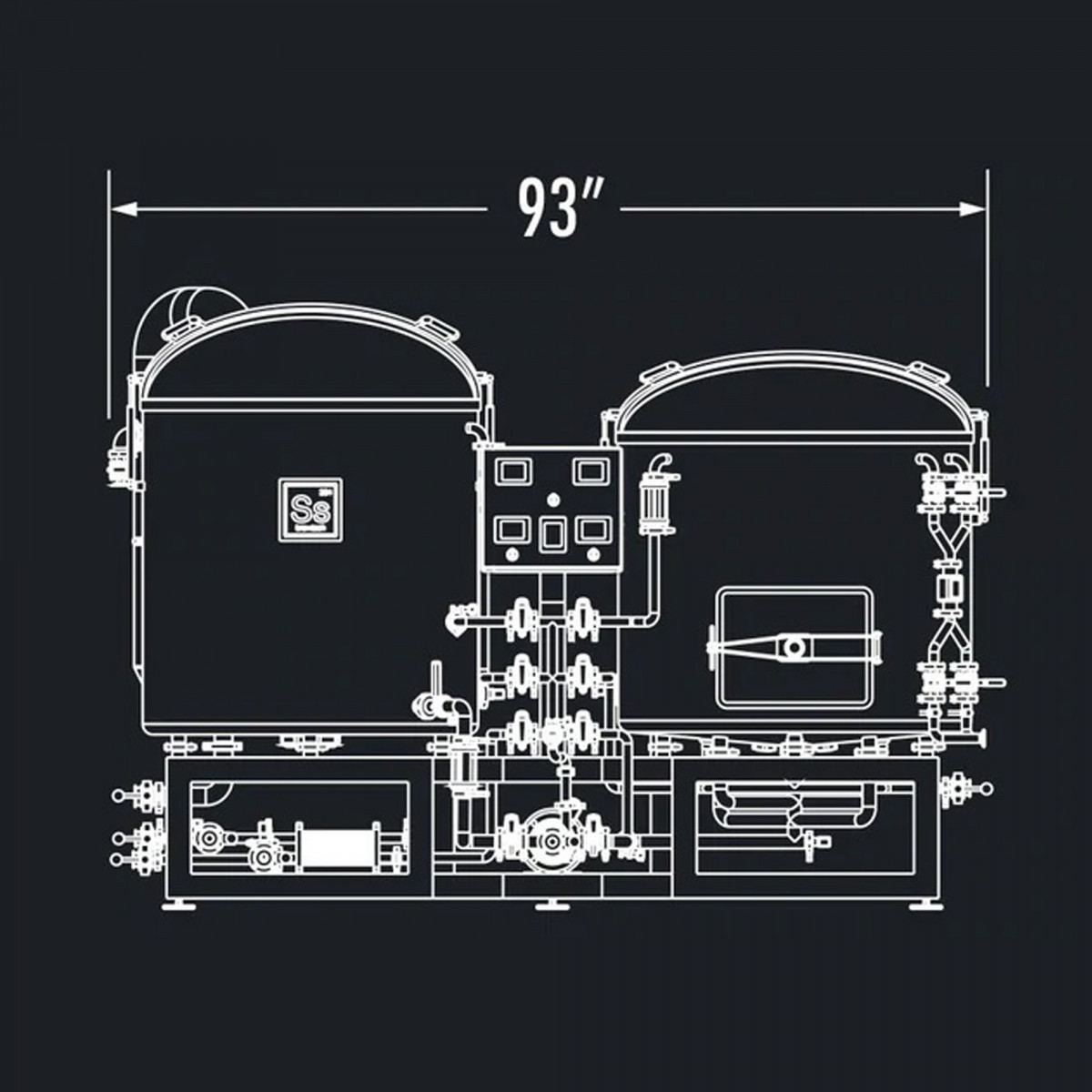

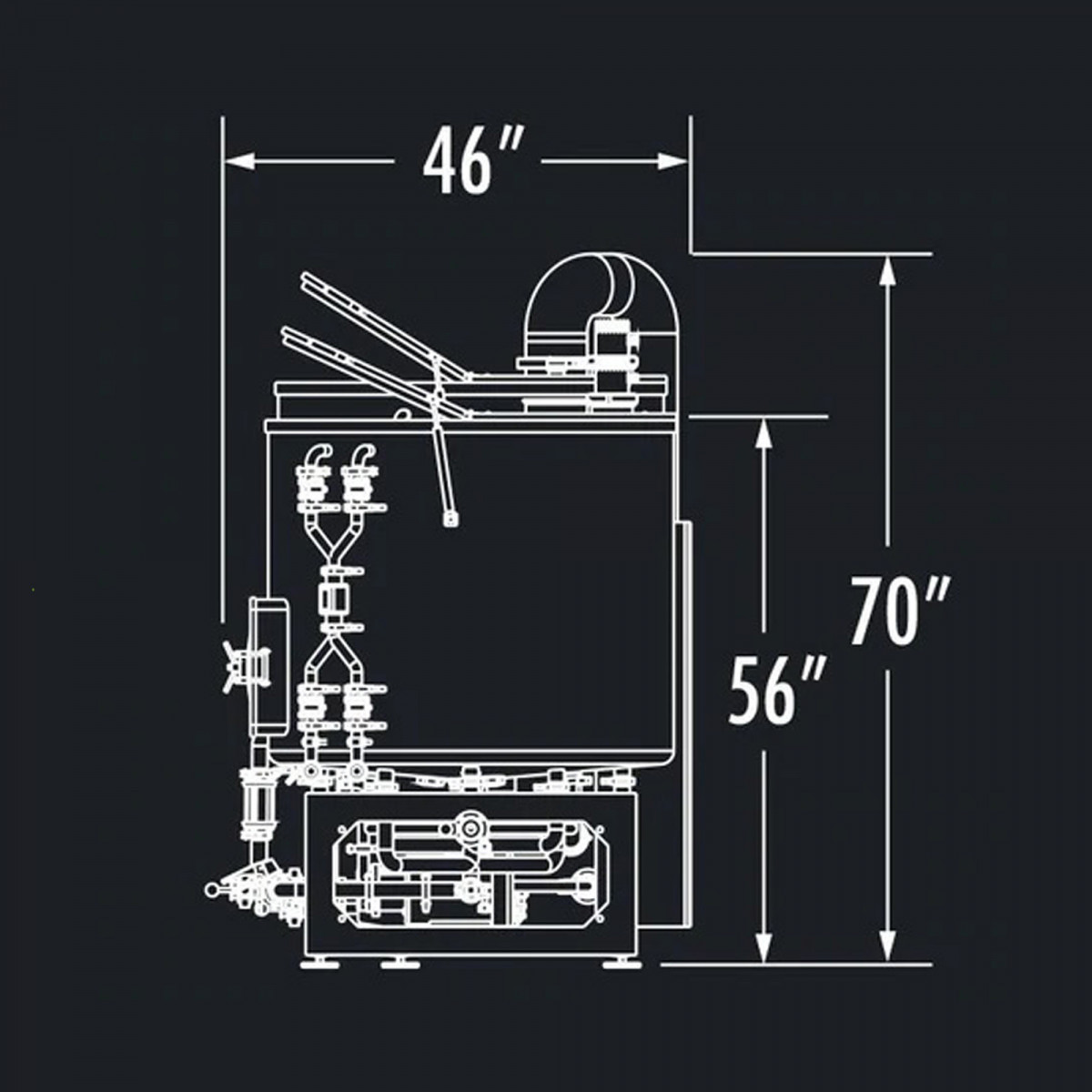

Dimensions (incl. Packaging)